In the world of power electronics, IGBT modules play a pivotal role in converting and controlling electrical power. These modules, which stand for Insulated Gate Bipolar Transistor, are essential components in various applications ranging from renewable energy systems to industrial automation. With their ability to handle high voltage and current levels, IGBT modules provide efficient and reliable solutions for power conversion requirements. By exploring the capabilities and applications of these modules, we can truly unleash the power they offer in shaping our modern technological landscape.

Benefits of IGBT Modules

IGBT modules offer enhanced performance, efficiency, and reliability in various applications. By integrating power semiconductor devices into a single module, IGBT modules simplify the design process and reduce the overall size of electronic systems. This compactness contributes to space-saving benefits, making them ideal for use in industries where space optimization is crucial.

One of the key advantages of IGBT modules is their capability to handle high current and voltage levels. This high power capacity allows for the efficient control of electrical energy, making them indispensable in demanding applications such as motor drives, renewable energy systems, and industrial automation. The ability to operate at these levels ensures stable and consistent performance even under challenging operating conditions.

Moreover, IGBT modules exhibit excellent switching characteristics that enable rapid and precise switching of high power loads. This fast switching capability minimizes power losses and ensures efficient energy conversion, leading to improved overall system efficiency. Combined with the ability to operate at high frequencies, IGBT modules enable sophisticated control strategies, enhancing system performance and responsiveness.

Applications of IGBT Modules

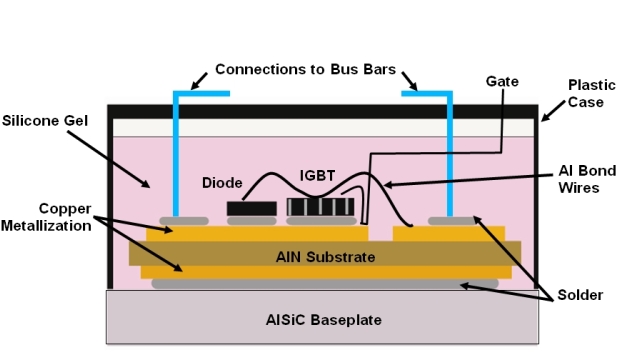

IGBT Module

Inverters are a common application of IGBT modules in various industries such as renewable energy, electric vehicles, and industrial motors. These modules enable the conversion of DC power into AC power efficiently, making them an essential component in modern power electronics systems.

Another key application of IGBT modules is in motor drives, where they control the speed and torque of electric motors. By switching the IGBTs on and off, these modules regulate the power supplied to the motors, resulting in precise control over the motor’s performance.

IGBT modules are also widely used in welding equipment for their ability to provide high power density and fast switching speeds. The modules help deliver the necessary power for welding processes, ensuring optimal performance and reliability in various welding applications.

Future Trends in IGBT Modules

As technology advances, the future of IGBT modules is poised for significant developments. One key trend to watch is the increasing demand for higher power density in IGBT modules. Manufacturers are striving to enhance the power capabilities of these modules while keeping them compact in size.

Another important trend is the integration of intelligent features into IGBT modules. This includes functionalities such as overcurrent protection, temperature monitoring, and fault diagnostics. By incorporating these smart features, IGBT modules can offer improved reliability and efficiency in various applications.

Additionally, the push towards wide bandgap materials like Silicon Carbide (SiC) and Gallium Nitride (GaN) is expected to shape the future of IGBT modules. These materials enable higher operating temperatures, lower energy losses, and enhanced performance, paving the way for more efficient and advanced IGBT modules.