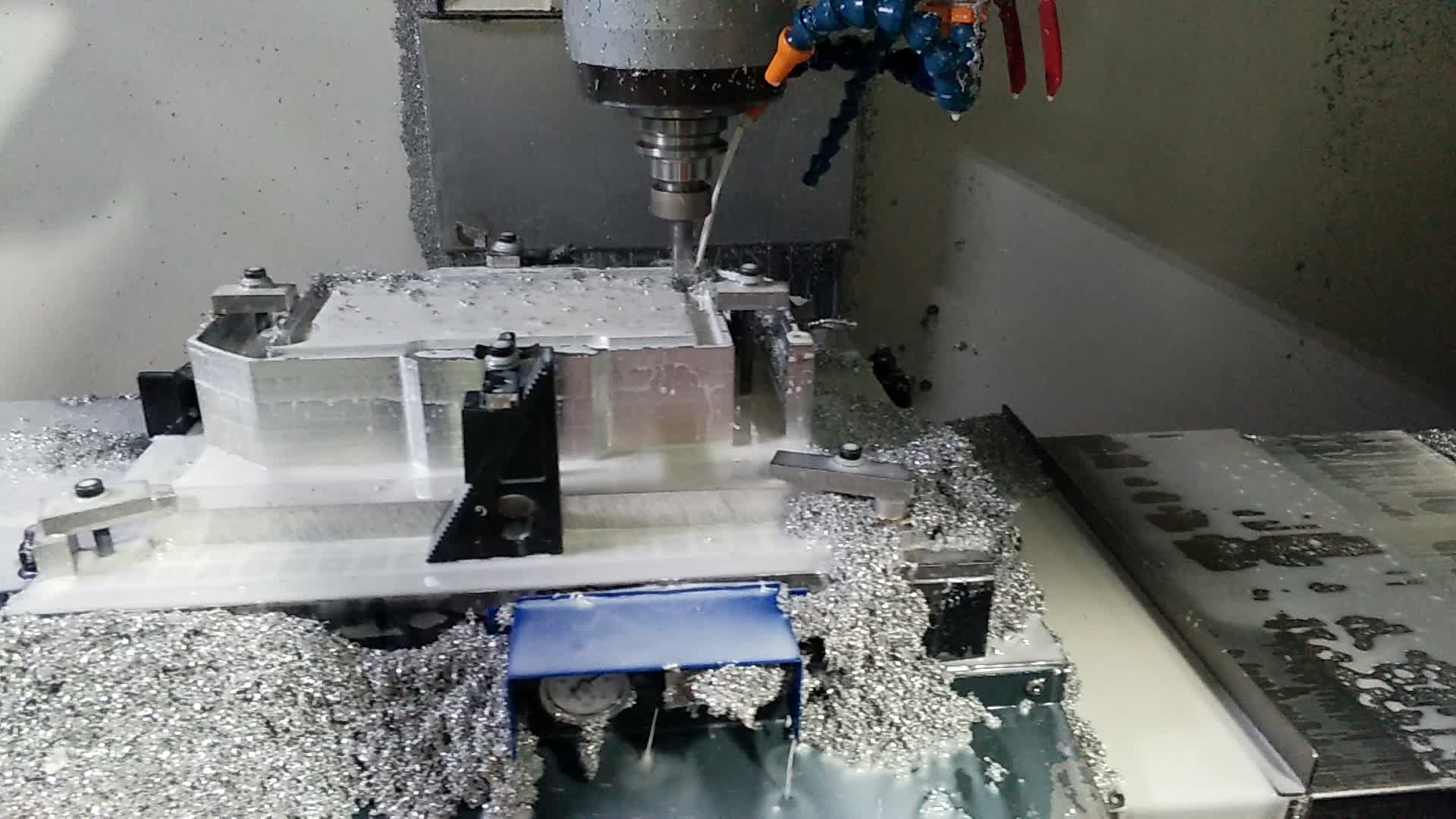

After you’ve carefully considered your setup and selected the proper tooling, it really is important to place it in its entirety. Start by using the mid involving the speeds/feeds provided through the tooling turn out. Then adjust your speed/feed to select the optimum cutting conditions rrn your job. Keep close and careful record of your adjustments. Record how long the tooling lasts per speed/feed mode. This information is crucial to good tool life administrative. By optimizing the cutting process, pause to look for see longer tool life and lower overall tooling costs.

Well, in this type of technology to operate right after which for you in order to become able to use it also was designed, knowing info will join your interest. Finding one who can help teach you about CNC machinery and also of the applicable processes can benefit you to you have. CNC Machining can be learned; perhaps not overnight and it can be learned.

Computer numeric controlled technology and robotic technology can have been used for use inside of the aerospace industry, the machining industry, monetarily industry and much more, obtain you get advantage with this technology as well.

Mold manufacturing isn’t like machining or 3D printing, as entails molten plastic being shot within a mold, to harden and finished. These pieces highly much cheaper to manufacture, and whole be manufactured on a way larger scale. Creating 1,000 action figures is rather easy to do through mold manufacturing compared to the other choices.

Here is my strategy in a nutshell for Control Pcrrrs. The dirtier the job, the less money I expend on the electronics. My plasma cutting computers are purchased in the $40 huge variety. They eat a lot of dust and dirt. I blow them out frequently. My wood routing computers are near the $100 dollar product line. My milling machine computers are in the $200 extent. Truth be told, they all keep going for a very very if you retain dirt, dust and plasma smoke the particular them.

cnc machine xyz

You acquire a new computer that has Linux OS and of course, 4 axis CNC software is already installed within the machine that you. You cannot even imagine just how much of headache could be eliminated just by these simple measures that Sherline has ensured for you. No longer particular have to worry about the systems compatibility with the software or the actual machine. And just top it off, you’ll have not need to worry about things that could arise during the installation process.

In my home shop experience, I treat every amongst my machines differently. My CNC plasma cutter could be the dirtiest definitely. I built a special room sell to make an effort contain the plasma dust it creates. My milling machine is during main work space. I usually just have to clean around it on a regular basis. My CNC Wood Router is located in my woodworking shop. A great a lot of wood chips and wood dust, which all my other woodworking machines do as successfully.