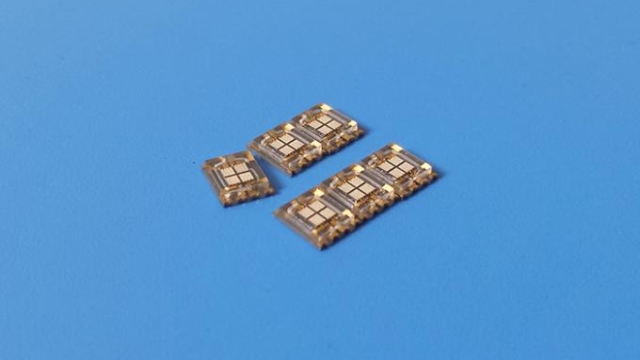

UV LED chips are revolutionizing the world of lighting technology, offering exceptional performance and efficiency in a compact package. These chips emit ultraviolet light, a wavelength that is essential for various applications such as sterilization, curing, counterfeit detection, and more. With the continuous advancement in UV LED chip technology, these innovative devices are becoming increasingly popular across industries.

One prominent player in the UV LED chip market is tianhui-led, a leading manufacturer known for providing high-quality UV LED chips that meet the demanding requirements of various industries. tianhui-led’s UV LED chips are designed to deliver powerful and reliable performance, offering a wide range of wavelengths and power outputs to suit different applications. With tianhui-led’s cutting-edge technology and commitment to innovation, UV LED chips continue to drive progress in the world of lighting and beyond.

UV LED Chip Technology Overview

UV LED chips are a cutting-edge technology revolutionizing various industries with their compact size and energy efficiency. These chips emit ultraviolet light when an electric current passes through them, making them ideal for applications such as sterilization, curing, and counterfeit detection.

One of the leading providers of UV LED chips, "tianhui-led," has been at the forefront of advancing this technology. They offer a range of high-quality UV LED chips that are utilized in a wide array of products, from water purification systems to medical devices.

The key advantage of UV LED chips lies in their longevity and eco-friendliness. Compared to traditional UV lamps, UV LED chips have a significantly longer lifespan and consume less energy, making them a sustainable choice for businesses and consumers alike.

Advantages of Tianhui-led Chips:

Tianhui-led chips offer exceptional performance in terms of efficiency, ensuring that they consume less power while delivering high output. This makes them an ideal choice for applications where energy efficiency is crucial. Additionally, the superior design of Tianhui-led chips results in enhanced durability and longer lifespan compared to traditional UV LED chip options.

Moreover, Tianhui-led chips are renowned for their versatility, allowing for customization to meet specific requirements of different industries. This flexibility in design enables the chips to be tailored for a wide range of applications, from medical devices to water and air purification systems. The technology behind Tianhui-led chips ensures consistent performance and reliability, making them a preferred choice for demanding applications.

Furthermore, Tianhui-led chips offer precise control over the wavelength of emitted UV light, making them suitable for various specialized uses such as curing, sterilization, and counterfeit detection. This level of control ensures optimal results in specific applications where accuracy and reliability are paramount. Overall, the advanced features of Tianhui-led chips make them a leading choice in the field of UV LED technology.

UV LED suppliers

Applications of UV LED Technology

One key application of UV LED technology is in water and air purification systems. UV LED chips are utilized to disinfect water by deactivating harmful microorganisms like bacteria and viruses, providing a chemical-free and cost-effective solution for ensuring clean and safe drinking water.

Another important use of UV LED technology is in medical and healthcare settings. UV LED chips are employed for sterilization purposes in hospitals, clinics, and laboratories. By emitting ultraviolet light, these chips help in disinfecting medical equipment, surfaces, and even the air, reducing the risk of healthcare-associated infections.

UV LED technology also finds applications in the field of UV curing for various industries such as printing, adhesives, and coatings. UV LED chips are used to initiate a photochemical reaction that quickly hardens materials, leading to improved efficiency in production processes. This environmentally friendly curing method is gaining popularity due to its energy efficiency and reduced carbon footprint compared to traditional curing methods.